This post was originally published in my Substack newsletter

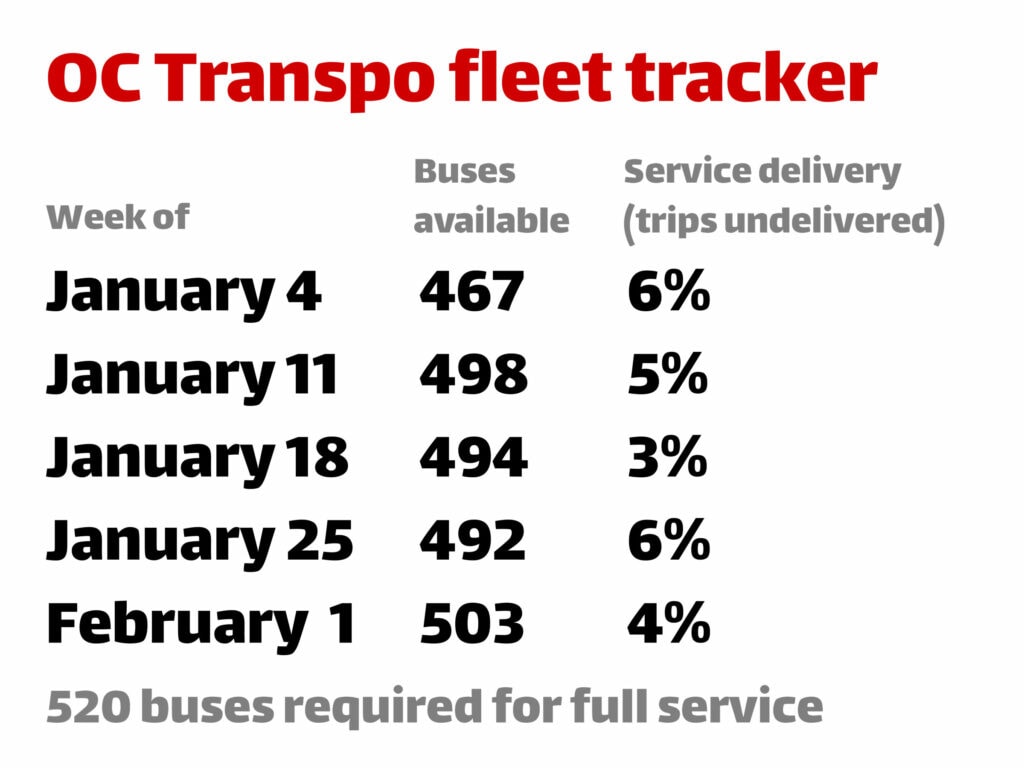

OC Transpo has been publishing weekly updates every Friday with information about the number of buses and trains in service. Over five weeks, we’re seeing slow but steady progress to stabilize the bus fleet.

The small improvements are largely thanks to new electric buses arriving (49 now in service), and a reduction in the maintenance backlog. We went into a high degree of detail on what’s happening with the bus fleet at Transit Committee yesterday, and I’ve shared a link to the presentation slides and full YouTube video on my web site.

***

On the rail side, we’ve been steady at 20 or 21 trains available for service each weekday. Seems like every time a vehicle returns to service, another one is taken out for routine maintenance and inspections. Single-car trains are still running every 3-4 minutes during the peak periods and for the most part that’s enough capacity. But it leaves no margin for error in the event of an unexpected issue, of which we’ve had several.

OC Transpo Interim General Manager Troy Charter was on CBC Ottawa Morning again today and his 10-minute interview gives a pretty good recap of what we covered at committee. A few key points:

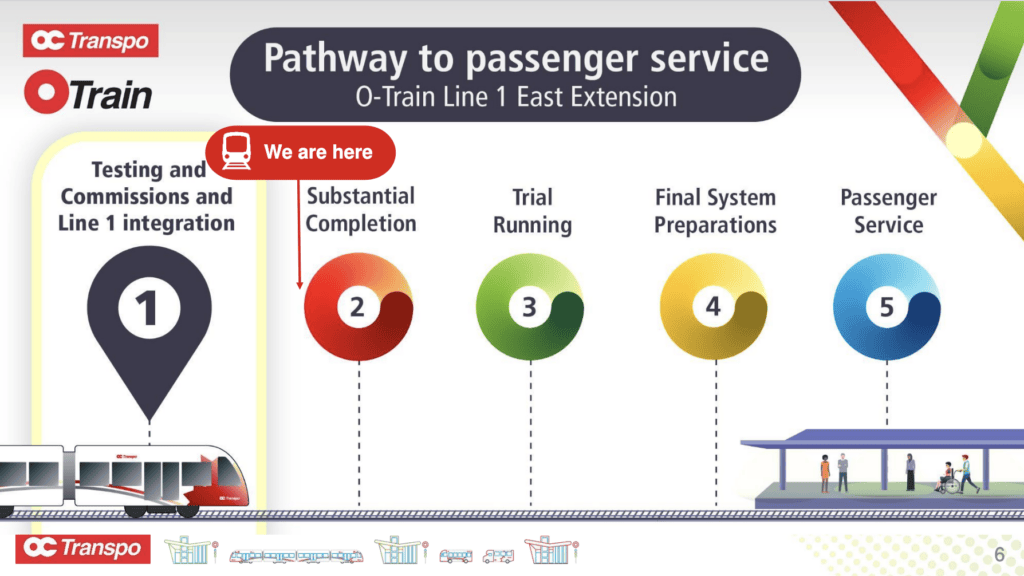

On what’s preventing the start of trial running for the Line 1 East extension to Trim Road: “Right now we’re down to a few key issues. The main one is what we call ‘platform edge cameras’. These are the CCTV cameras that give a view to the operator that the train is safe to depart the station. So obviously that’s a critical safety feature that we need to make sure that it’s rectified before we go into service. So that’s the main primary issue right now that the teams are working through is resolving some of the camera angles and deficiencies associated with these CCTV cameras.”

On whether the lack of vehicles due to the spalling issue will hold up trial running and launch of the train: “It’s not affecting things on the extension at this time. I would prefer to be running trains and practicing and doing all that work in advance, but we know that we’ve done practice exercises. We had our operators out on the line – we ran 23 trains last year – so we know that we can run the 23 trains, we’ve done it reliably. Right now though the reduction in the number trains is not impacting our ability to move towards substantial completion. But I’ve been clear in saying that to proceed to trial running we will need more trains available. So that could cause an impact that if we don’t resolve the issue between now and substantial completion achieved. So I’ve got our rail construction team – they’re focused on the rail construction, achieving substantial completion. And then I’ve got our engineering team and our OC team here working with RTG and Alstom who are responsible for the vehicles and the spalling issue to come up with a solution, both short-, medium-, and long-term, so that we can get into service.”

On how long it might be before there are significantly more trains back: “[RTG is] replacing any of these cartridge bearing assemblies or axles that have over 100,000 kilometers. That’s where you’re seeing the slow growth from 18/19/20/21 [trains]. But in parallel to do that we’re working with their engineers and their bearing experts to validate processes, tools and procedures that can identify if spalling exists on the cartridge bearing assemblies, so that we can confirm that the fleet is safe to continue operation… That would allow us to reassess the 100,000km restriction to maybe go to 200,000km or even possibly completely remove… To be fair to RTG, they have said that the fleet is safe for continued operation. And the City said ‘well OK that’s great but out of an abundance caution we want to see the information, we want to validate all the processes, we want to validate the tools you’re using, we want to see that information and then we can reassess that 100,000km restriction.’ …And in the long term obviously is we need to continue with all the root cause analysis and investigation so that we have a permanent solution moving forward.”

On how the redesign of the cartridge bearing assemblies – the “sustainable solution” is coming along: “RTG has started to supply us with the necessary technical information design drawings for a redesigned cartridge bearing assembly so they’ve advanced that process and we’re starting … they’re doing their evaluation on ‘are we ready to go to a prototype phase’ and they’re including us in those discussions… work on the redesign is progressing.”